Metalworking & Other Products

In addition to our core lighting business, we are able to offer a variety of metalworking processes, solutions and products

The technologies we work with

Laser cutting

Bending

Spinning & Turning

Milling

Powder Coating

Extruding

SLA 3D Printing

Metal Details

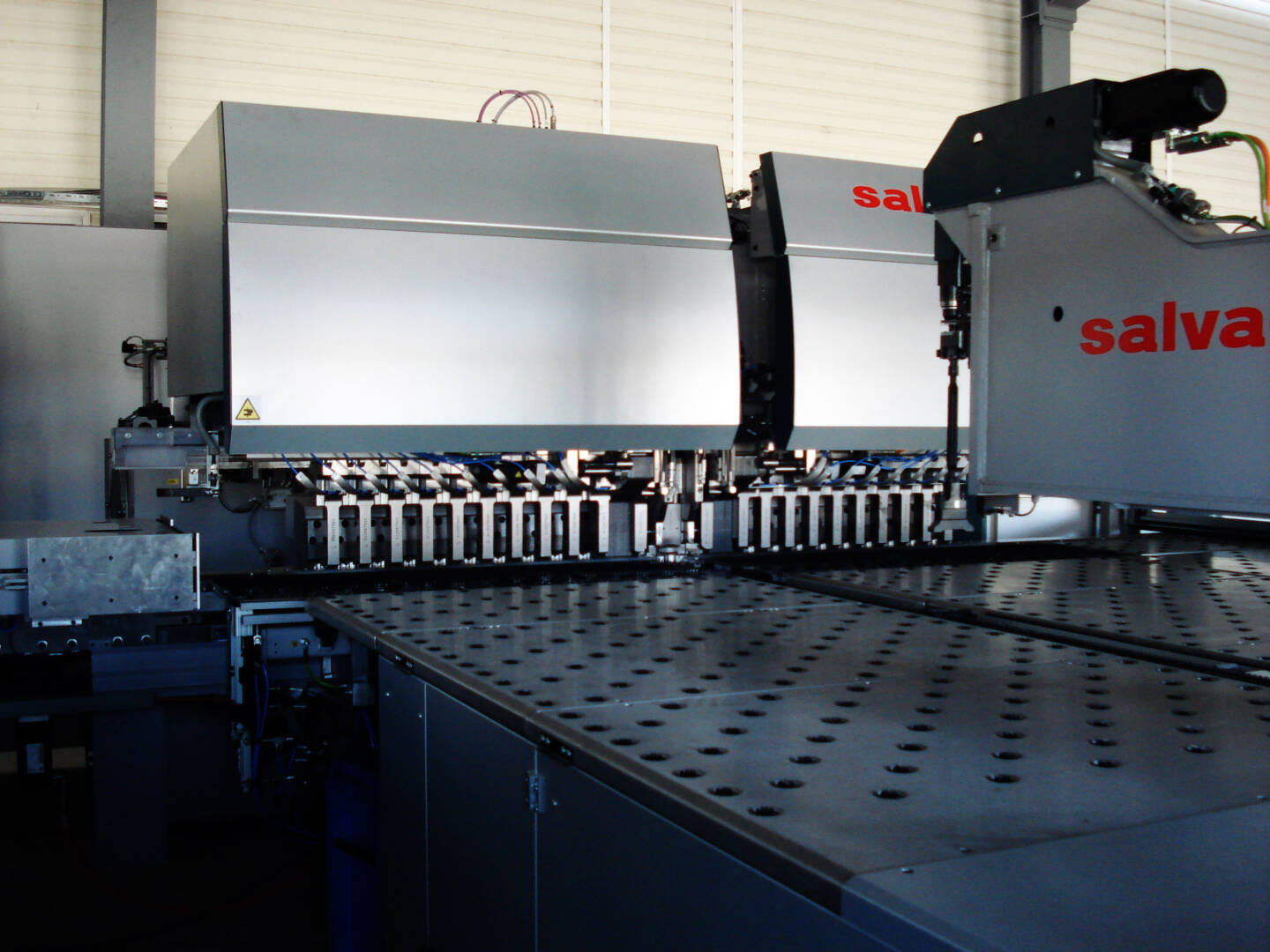

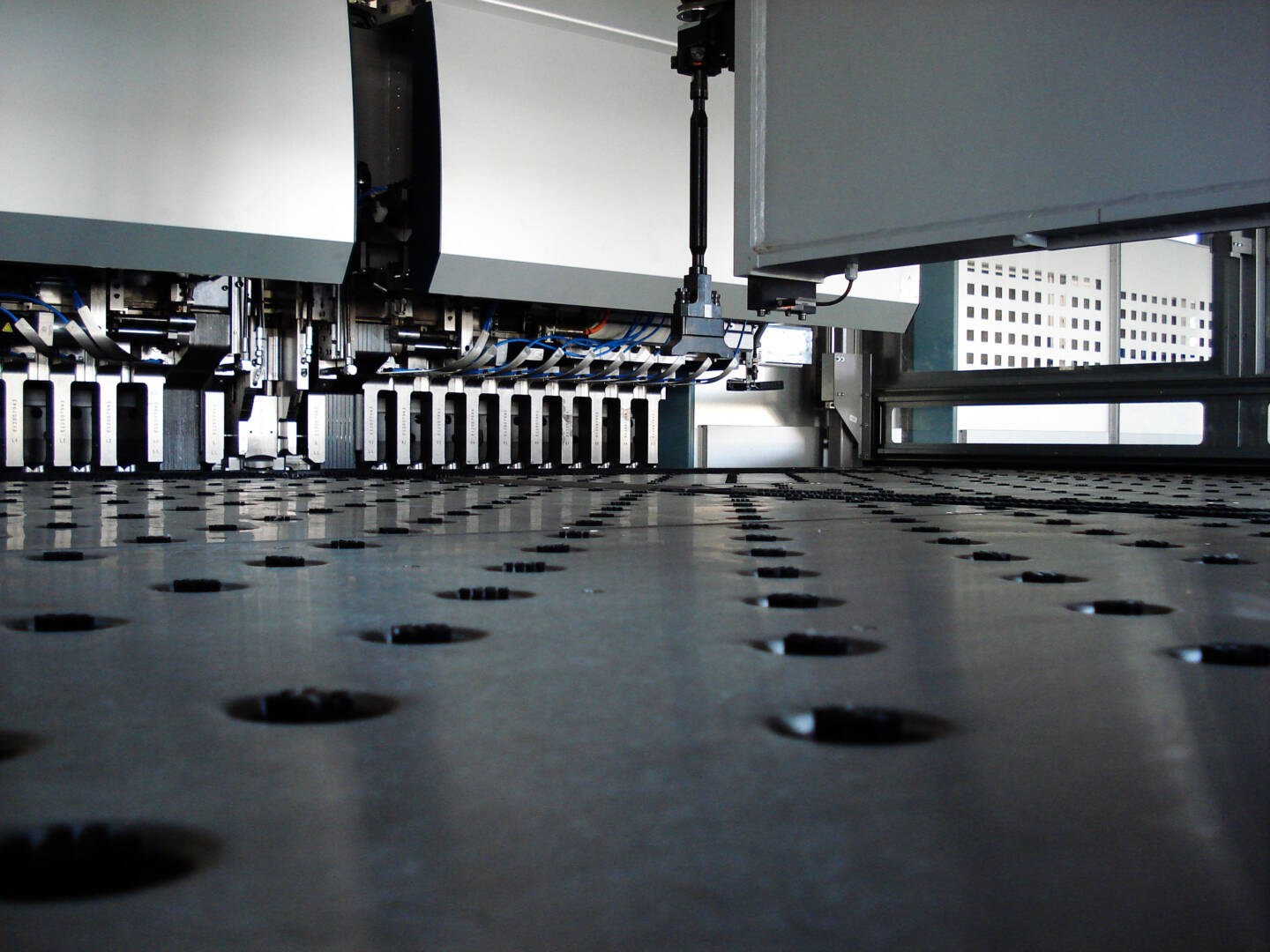

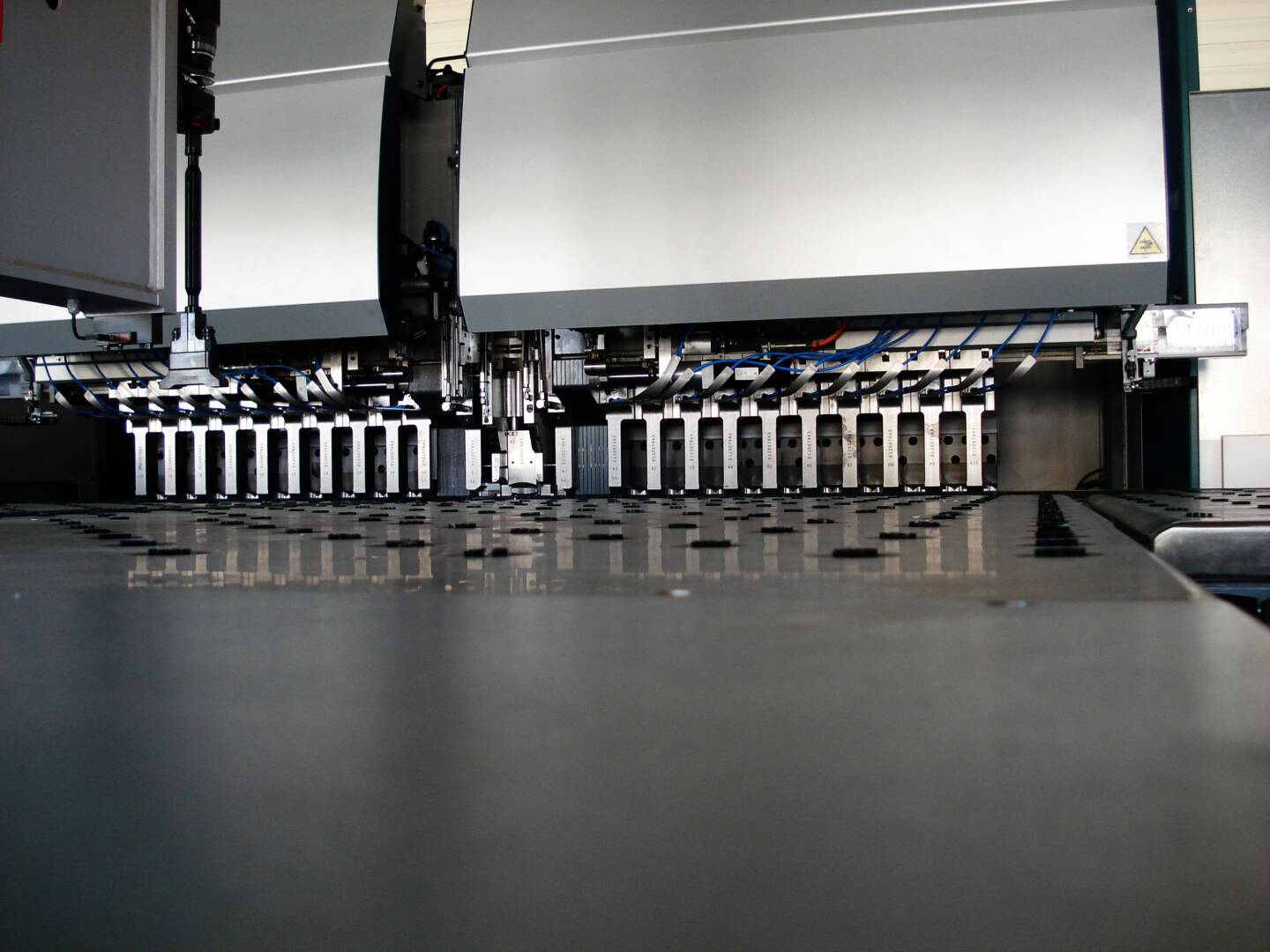

Laser Cutting

Under our disposal are two fiber laser machines 6kW and 2kW laser and One Tube Laser.

With them, on a daily basis, we cut S235JR, S355JR, 6061 Aluminium, Stainless steel 304 and mirror aluminium sheets metals.

For the full capabilities of our machines look into our machine specification presentation.

Details:

Characteristics of automatic bender:

Maximum length of incoming sheet (mm): 2190

Maximum width of incoming sheet (mm): 1524

Maximum Bending length(mm): 2180

Maximum thickness and bending angle of steel ( s235jr ):

2.0mm (90 degrees); 2.0mm (120 degrees of bending); 2.0mm (135 degrees of bending)

Maximum thickness and bending angle of stainless steel:

2.0mm (90 degrees), 2.0mm (120 degrees), 1.6mm (130 degrees)

Maximum thickness and bending angle of aluminium:

2.0mm (90 degrees), 2.0mm (120 degrees), 2.0mm (130 degrees)

In addition to the automatic panel bender we have three Manual Press Brake machines used for thicker metals:

Most of our luminaires go trough this process. Feel free to have a look at our product page for a general overview.

CNC Spinning and Turning

We operate several lathe machines.

*Two spindle with Y axis lathe - OKUMA LB3000 EXII MYW DBC450

with Ø5μm 24 hour constant precision

* Lathe with tube feeder used for our own fastener solutions

* Two spinning machines

Technical parameters of Spinning machines

| Maximum Material Diameter | mm | 800 | |

| Support Plate Barrel Diameter | mm | N/A | |

| Spindle Center Height | 400 | ||

| Distance between Two Centers | 600 | ||

| Main Motor Power | kw | 20frequency conversion | |

| Spindle Speed | rpm | 30-2000 | |

| Stroke | Horizontal X Shaft | mm | DIA-700 |

| Stroke | Vertical Z Shaft | mm | 500 |

| Maximum Jacking Force | kn | 25 | |

| Jacking Stroke | mm | 600 | |

| Thrust Reverser Stroke | mm | 400 | |

| Positioning Accuracy | 0.01 | ||

| Hydraulic Station Motor Power | KW | 5.5 | |

| Tool Quantity (Optional) | Unit | 4/8/1 | |

| Processing Material Thickness | Copper, Aluminum Thickness | Mm | 0.5-6.0 |

| Processing Material Thickness | Steel Thickness | Mm | 0.5-3.0 |

| Processing Material Thickness | Stainless Steel Thickness | Mm | 0.5-2.5 |

Products and Details:

For more information about the machines specifications download our machine presentation or write to us via email

CNC Milling

5 Axis vertical machining center- OKUMA GENOS M460V-5AX

The spindle produces less vibration and power loss at the tool tip for outstanding surface finishes and metal removal rates.

Surface finish up to 0.4 Ra

Maximum Detail dimensions:

Χ: 600mm

Υ: 600 mm

Ζ: 400 mm

Details and assemblies

The Extrusion profiles we produce:

SLA 3D Printing

SLA or Stereolithography 3D printing is the most common resin 3D printing process that has become vastly popular for its ability to produce high-accuracy, isotropic, and watertight prototypes and end-use parts in a range of advanced materials with fine features and smooth or matte surface finish.

Layer height 0.01-0.015

Accuracy 0.01mm

Printer Dimensions – 300mm x 298mm x 164mm