Linea In KNAUF - Knauf / False Ceiling / IP20 Linea in Line is a continuous robust lighting system. Our solution offers designers the ability to create seamless lines without any light spillage. Future proof

Linea In Line - Linear / Surface / Suspended / Direct - Indirect / IP40 Linea in Line is a continuous robust lighting system. Our solution offers designers the ability to create seamless lines without

ROBY SERIES IP20 ROBY SURFACE/ RECESSED/ PLASTERBOARD IP20 Series: Standart Sizes: 595х595mm 295х595mm 295х1195mm Advantages: Thanks to the wide range of optics, module sizes and mounting methods (lay-in, recessed and surface-mounted solution), all lighting tasks

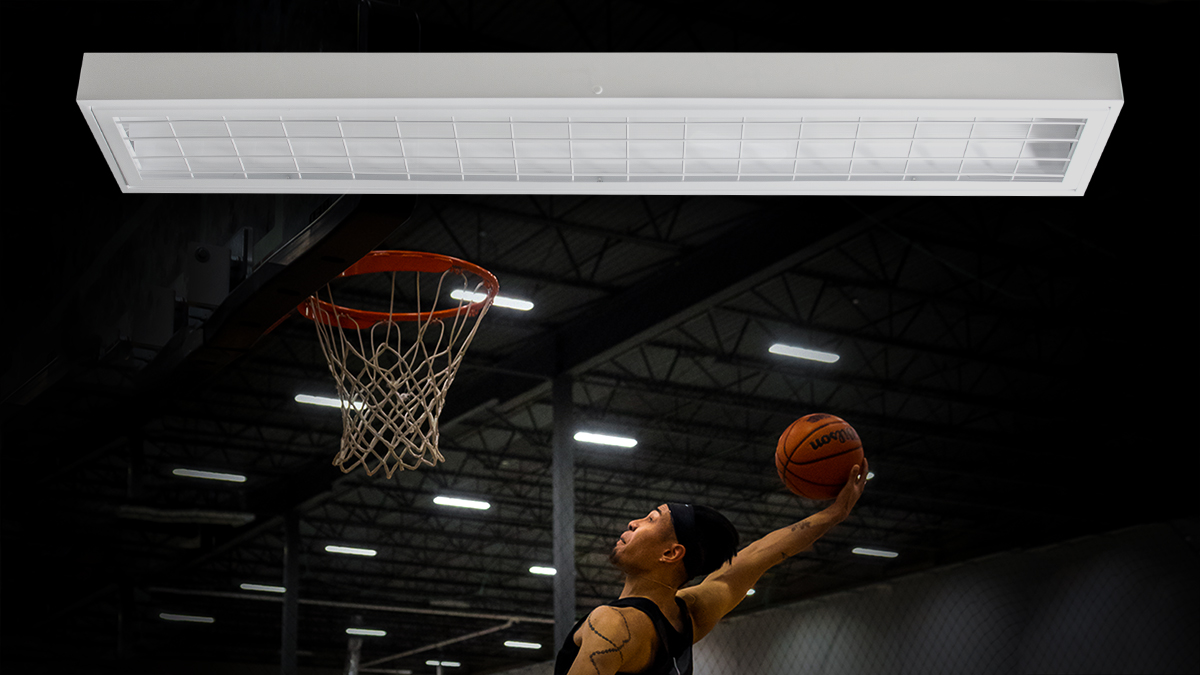

SPORT HALL IK10 / IP40 SPORT HALL IK10 / IP40: 95W - 11500 lm 125W - 15100 lm 145W - 17400 lm 205W - 24600 lm Advantages: SPORT HALL Lighting Fixture covers the high requirements in this area in

LUMAX Industrial IP43 LUMAX Industrial IP43 Series: L 1015mm - 60W - 9000lm L 1515mm - 90W - 13500lm L 2015mm - 120W - 18000lm Advantages: An innovative product manufactured under the highest of European

New Dexter 1R / 3R / Fish bone Suspended in line / Surface in line / Track adaptor Pride to present our NEW DEXTER, comes with 1R & 3R options and in lengths of 1200mm,

EDDIE SERIES IP20 Surface / Pendant / Pendant Direct - Indirect EDDIE SERIES comes with different profile sizes - 36x67mm, 50x75mm and 75x100mm and with lenghts between 580mm and 1700mm. Direct - Indirect option is